ULTRA LIGHTWEIGHT CARBON FIBRE FOOTBRIDGE

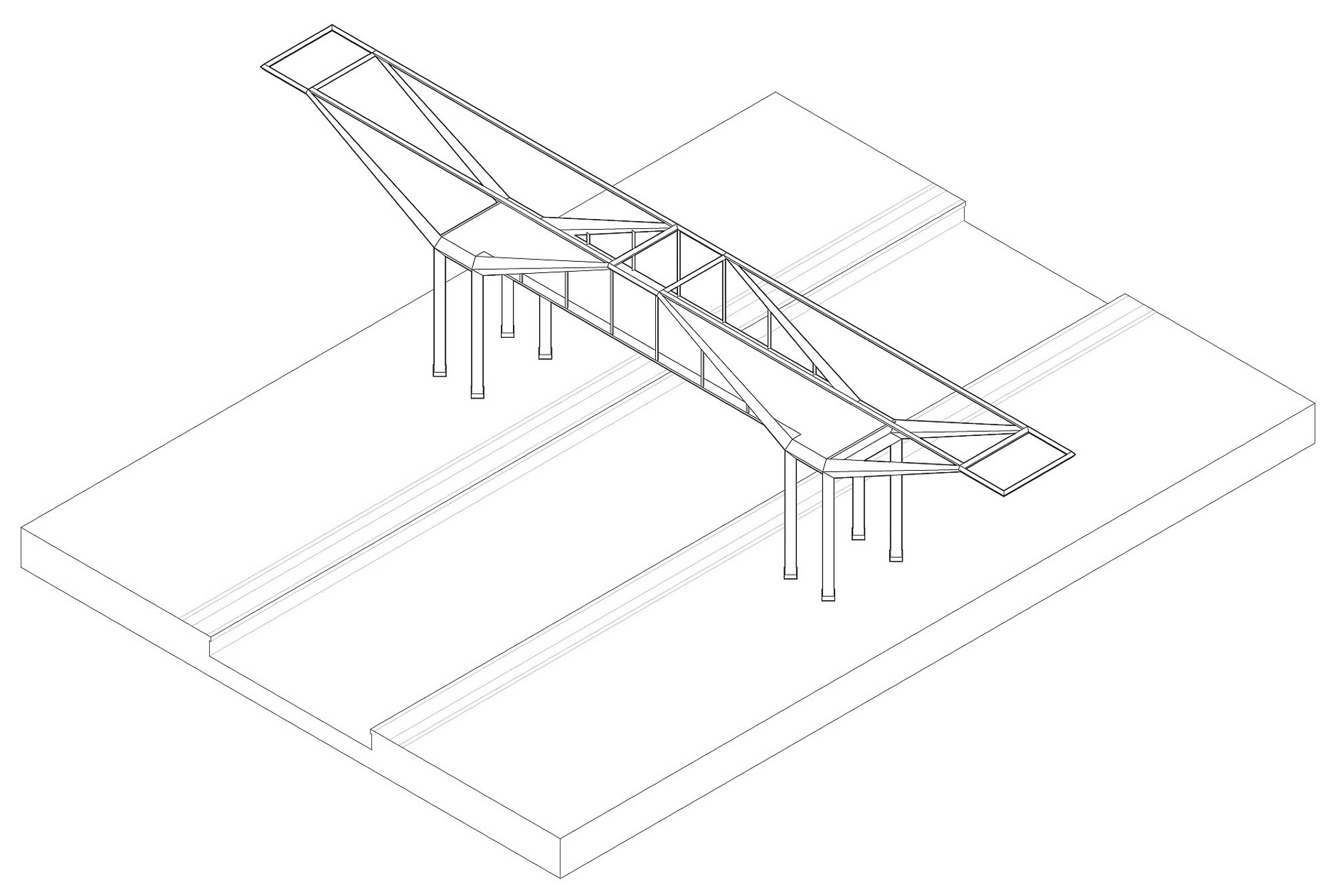

Inspired by the latest advancements in automotive and aerospace cutting edge technologies, our design proposal combines the advantages of composite structures with a form-finding approach which aims to minimise material mass through a very efficient distribution of forces and structural optimization.

Our design ambition is to create an aesthetic that embodies the ethos of the ushering in of a new age for the British rail industry with a state of the art approach. The medium through which the message is conveyed is by the use of carbon fibre composites, a material which best encapsulates the very essence of today’s technological achievements.

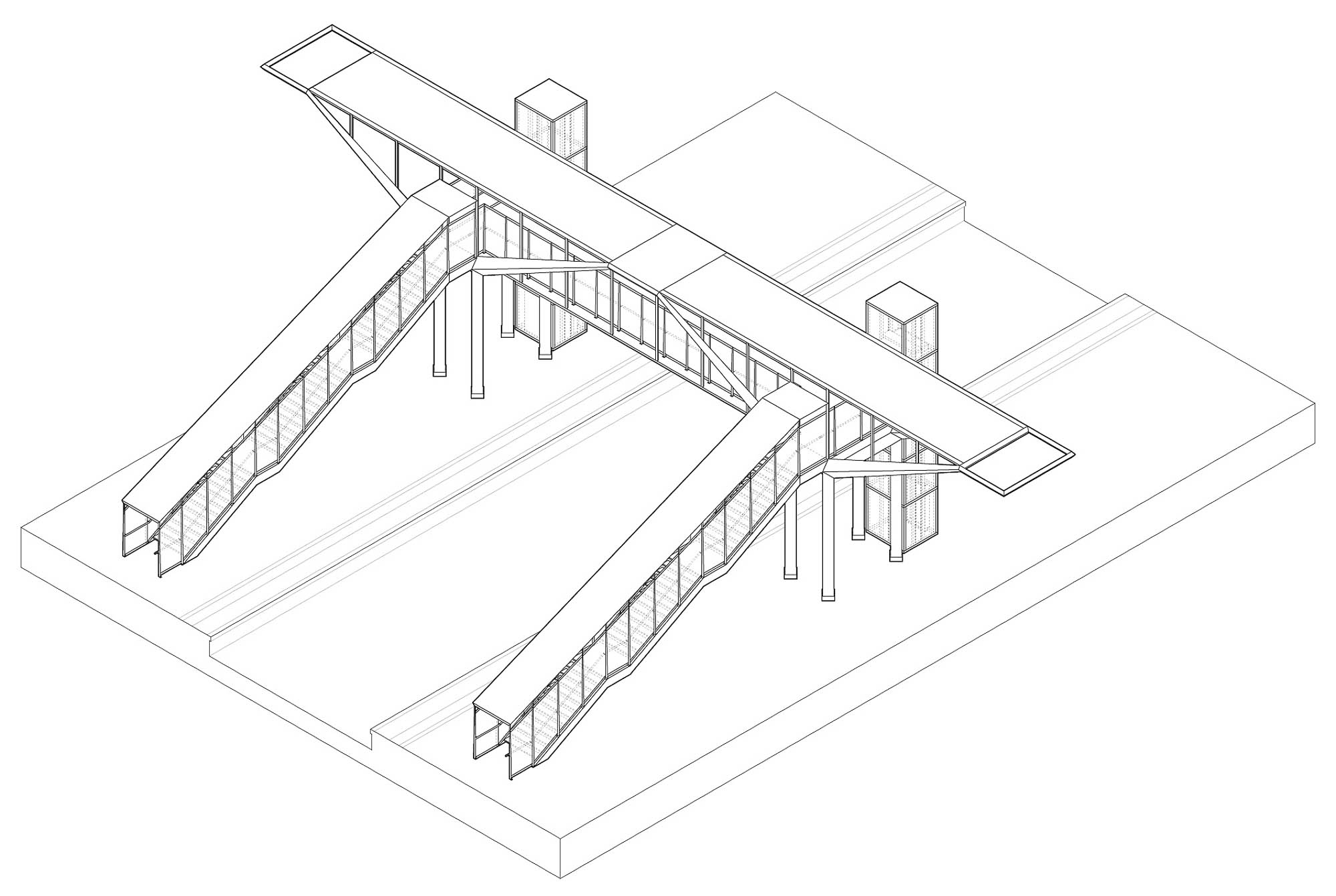

Spanning across the rail tracks, a lightweight transparent bridge link system connects the platforms from either side. In aspiring to attain a minimalistic optical imprint the overall assemblage boldly defines the visual presence of the rail infrastructure. The main element of the horizontal bridge assembly is the visually distinctive variable section inclined chord, which branches out from either side of the platform and comes together in the middle of the track. This cantilevering member supports both the functional bridge deck below and the roof vertical supports where necessary. However, in order to minimise the visual impact of the horizontal elements, the whole comes together to form a truss like assemblage. The bridge features panoramic glass lifts and stairs at either end to provide access to the station platforms.

All the bridge components are pre-fabricated in the factory, lifted into position and assembled on site in order to reduce site possession times and service disruption. The overall result is a kit of parts which offers a practical and simple approach resulting in a sleek and distinctive contemporary aesthetic that captures the spirit of the carbon allotropes era.

DATA

Client: Network Rail

Use: Pedestrian Bridge

Structure: Composite

Status: International design competition. Finalist

CREDITS

Architect: LUCA POIAN FORMS

Engineer: SOLUXN Ltd